It sounds spectacular, but it has already become feasible: the production of chemical base materials and fuel components from CO2 and water by means of eco-power (Power-to-Liquids (PtL)). And Nordic Blue (NBC, Norway) have committed themselves to exactly this goal. At present EDL and Sunfire (Germany) are performing engineering services for this project.

The process

The first step of the PtL process is the renewable generation of syngas (CO to H2). This gas originates either from a steam electrolysis and CO2 conversion by RWGS (Reverse Water Gas Shift) or from a direct electrochemical transformation by co-electrolysis. In a Fischer-Tropsch synthesis the syngas is then converted into hydrocarbons, the e-crude. The e-crude can then be further processed to high-valuable fuel components (e-fuels) and chemical base materials (e-chemicals). The existing gas station infrastructure and fuel logistics can be used further and these e-fuels can directly be applied in the existing combustion engines. I.e. vehicles of today are de facto CO2 neutral – a huge advantage compared to classic electromobility since purely electric powertrains will not be available on a commercial basis for heavy-duty and air traffic in the medium run!

The PtL process

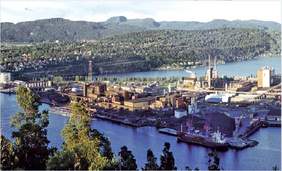

NBC intends to build the first PtL plant to produce raw e-waxes and e-fuels in the Norwegian industrial park of Heroya, located 140 km southeast of Oslo. The plant is to produce 8,000 t of e-crude annually using 20 MW of power generated from hydropower.

As planned the SOEC (Solid Oxide Electrolysis Cell) technology by Sunfire will be applied for steam electrolysis in the plant in Norway. Mostly CO2 industrially produced as by-product at the neighboring site shall serve as carbon source. In addition to this CO2 from the air shall be captured using the DAC (Direct Air Capture) technology by Climeworks. For the RWGS stage as well as for the Fischer-Tropsch synthesis the use of commercially available catalysts is envisaged. In a downstream fractionation unit the separation into e-waxes and e-fuels takes place.

Engineering has started

Since summer 2017 the technological terms of reference have been implemented. A team of process engineers prepares balances and overall concepts. EDL investigates the technical feasibility of the individual process stages prior to selecting the suitable/optimal individual process technology. In the future engineering services related to equipment, piping, layout as well as a cost-benefit analysis will also be included in EDL’s scope of work.

Dr. Michael Haid, EDL’s CEO: „The combination of plant engineering know-how available at EDL, the creative search for the best possible technical and economic solutions and this innovative technology suit us excellently. Sunfire is deemed the pioneer in the field of SOEC technology which is being further developed to a co-electrolysis to produce syngas in one step without RWGS.“

Innovative technologies for refineries

Classic refineriescan improve their CO2 footprint by using the PtL technology to produce CO2-neutral Fischer-Tropsch hydrocarbons or methanol. In addition the hydrogen generation by electrolysis is also attractive.